Unlike picking out furniture for your home kitchen, selecting commercial shelving for your restaurant’s back of house (BoH) is a surprisingly complex task. Foodservice demands a specialized approach to storage, and we are here to help you make the best selection to meet the needs of your professional kitchen.

This shelving guide breaks down the strengths and weaknesses of different materials, the needs of different locations in your kitchen, and tips for passing your health inspection.

Materials, Weight Capacity, & Locations

Selecting the correct shelving material depends on several factors specific to your BOH operation. You’ll need to consider the strengths and weaknesses of each material, familiarize yourself with weight capacities, and think about the climate they’ll reside in.

Polymer Shelving

High-density polyethylene (HDPE) or polypropylene (PP) plastic with a non-porous surface is impervious to moisture, making it perfect for areas with high humidity or frequent cleaning. Additionally, its smooth surface is easy to clean and discourages debris buildup. It also works well for dry storage areas.

Polymer shelves are lightweight and easier to maneuver. It’s a quality material for a walk-in cooler or freezer as well as dry storage. However, it is not ideal for storing heavy equipment or bulk ingredients. With polymer, stick to storing food containers, utensils, and other lighter supplies.

In short, polymer shelving has a low weight capacity and works best in dry or cold areas.

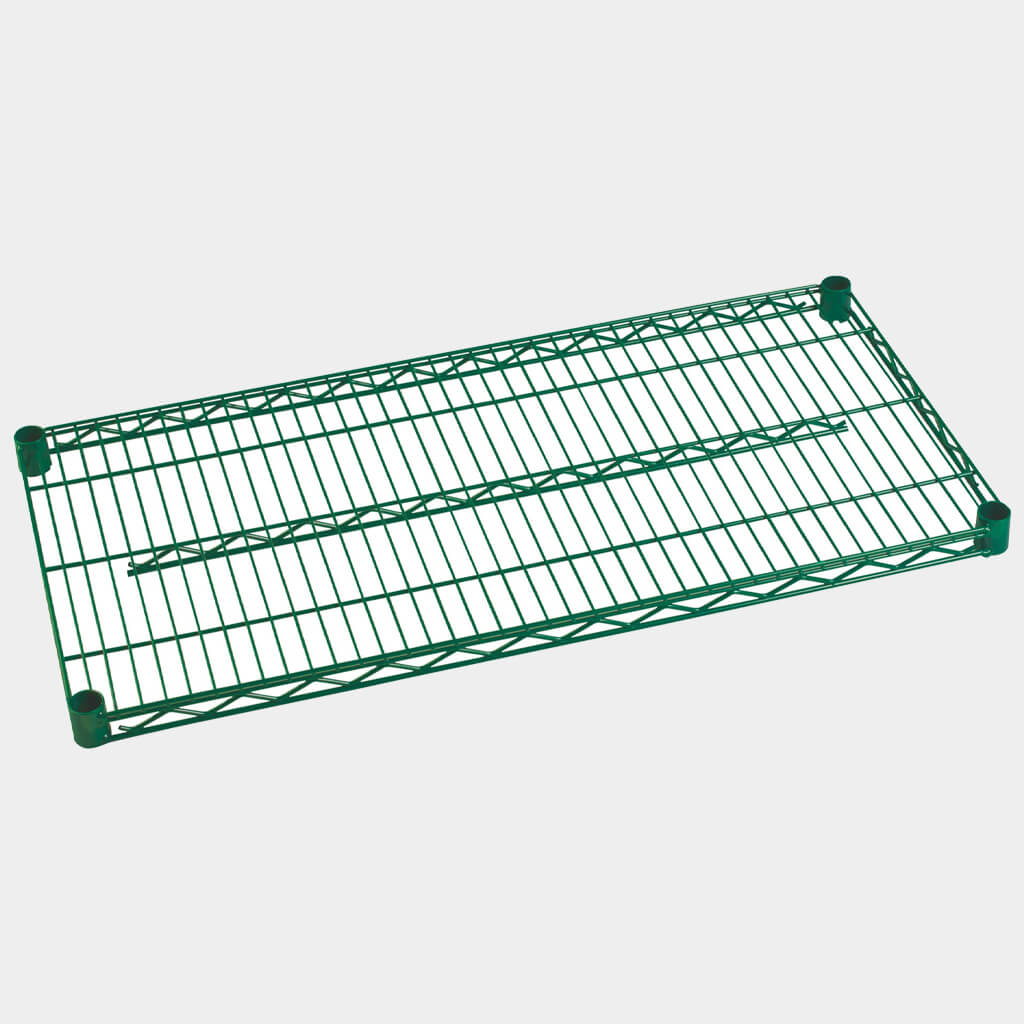

Wire Epoxy Shelving

Wire epoxy is a steel wire frame coated with a durable epoxy resin finish. This material is well-suited for storing canned goods, dry goods, and other non-perishables in dry or moderately humid areas.

Epoxy coating protects steel from rust and moisture damage. It is also tougher than standard wire shelves and suitable for storing heavier items.

Another benefit of choosing wire epoxy shelves is that they’re easy to clean, and the open wire design allows for air circulation which helps to prevent dust accumulation. Wire epoxy tends to be a cost-effective purchase that provides a balance between affordability and durability.

To summarize, wire epoxy shelving has a medium to heavy weight capacity and works well in most environments.

Chrome Shelving

Chrome shelves offer a bright finish and a lower price tag. Place chrome in dry storage areas and limit its shelves to lightweight items. If chrome is placed in humid areas or areas that require frequent cleaning, it tends to rust, which is a safety hazard.

In summary, chrome shelving has a light weight capacity and is perfect for dry storage areas.

Stainless Steel Shelving

When it comes to cookware, stainless steel is a commercial-kitchen hero. The same applies to shelving. High-grade, corrosion-resistant steel alloy offers strong, long-lasting material, ideal for withstanding heavy loads and demanding use. Its non-porous surface resists bacterial growth and is overall easy to clean. Although this isn’t the priority for the BoH, it does offer a sleek appearance complimentary to modern kitchen design.

The only tradeoff with stainless steel shelving is that it has a higher price tag than most and requires some muscle to move. Otherwise, it is perfect for storing heavy equipment, pots and pans, and bulk ingredients. Use stainless steel shelving in hot, humid areas or in walk-in coolers and freezers.

All in all, stainless steel has a heavy weight capacity, and works well in all climates.

Zinc Shelving

Compared to regular chrome, zinc-coated shelving offers improved corrosion resistance and can be purchased at a lower cost than stainless steel.

Its weight capacity is in the middle ground as well. Zinc shelves are suitable for storing moderate weight items in dry or low-humidity areas. They’re a good option for holding canned goods, dry ingredients, and other non-perishables where a slightly more corrosion-resistant solution is desired compared to regular chrome wire shelves.

In short, zinc shelving has a medium weight capacity and performs well in environments with low humidity.

Different Locations Have Different Shelving Requirements

As mentioned in our material descriptions, different environments require different shelving materials.

Dry Storerooms: Chrome or polymer shelving are all good options for room temperature, dry areas.

Walk-in Coolers & Freezers: Stainless steel’s durability and resistance to rust and corrosion caused by condensation makes it the industry standard for withstanding the cold and maintaining sanitary conditions.

Dishwashing Areas: Here, epoxy-coated wire shelving is ideal. A high-moisture environment, like a dishwashing area, demands shelving that is resistant to water and cleaning chemicals. The epoxy coating protects the metal from rust and is easy to clean.

For Health Inspectors, Rust Is a Red Flag

The care and maintenance you put into your shelving area is reflected in your health inspection report. The number one factor to look out for is rust. Rust flakes can contaminate food stored on the shelves or make their way onto plates and utensils. Rust also weakens the structural integrity of your shelves, potentially leading to broken equipment or spilled ingredients.

As we mentioned in our materials breakdown, stainless steel shelving is preferred for areas with high moisture or exposure to cleaning chemicals, as it resists rust and corrosion. The second best and more affordable option is epoxy-coated shelving.

Essential Considerations for Effective Commercial Storage

Shelving for professional kitchens requires the right materials, different kinds of shelving for different areas of your kitchen, and maintaining a rust-free environment. Have you ever witnessed a shelving disaster in a commercial kitchen? Share your cautionary tales in our comment section!