Welcome to the dish pit. The success of your business is riding on how efficiently this back of house job is done.

You decided to invest a little more money up front for a high temperature commercial dishwasher. They remove tougher foods and sanitize more effectively. In addition, these machines don’t require chemicals to kill bacteria. As a bonus, your dishes dry much faster due to the higher temperatures of those dishes when they come out of the machine.

Arguably more important, you hired an enthusiastic person who’s just crazy enough to be the nameless hero of your restaurant. Only the most experienced chefs and restaurant owners know how critical the role of warewasher is. The success of your restaurant hinges on the speed and efficiency of the crew operating your commercial dishwasher during rush-hour. Even so, there may be one important question you forgot to ask when building your dish pit.

The Unexpected Bottleneck of Commercial Dishwashers

Commercial dishwashing machines require very hot water to properly clean and sanitize your dishes. If that high temperature is not maintained, you must stop and wait for your commercial dishwasher’s hot water to recover.

Your dirty dishes begin backing up. In the meantime, your new crew member is taking out the trash and delivering larger cookware to the chefs. Your staff waits for the dishwasher’s hot water to recover. Now you have a bottleneck in your kitchen.

Seconds add up to minutes and time is money.

You never planned on having to wait for your dishwasher to recover. You were so careful to purchase the best dishwashing machine for your space and business. Also, you were lucky enough to find someone who shows up on time every day to operate the machine. So what went wrong and why the bottleneck?

The answer is elusive, yet simple: Your booster heater is too small or failing.

Turning Up The Heat

Before we go into what exactly a booster heater is – let’s review what it means to “sanitize” dishes.

To sanitize dishes and satisfy your health inspector, water used in the final rinse of your wash cycle is required to reach 160°F for a stationary rack or at least 180°F for all other types.

180°F is the temperature required to sanitize and meet sanitation regulations as determined by the National Sanitation Foundation (NSF). The standard known as NSF / ANSI 3 requires commercial dishwashers to eliminate 99.999% of microorganisms and bacteria. This is also known as a 5-log reduction.

This standard exists because the surface of dishes must reach 160°F for 10 seconds. This is achieved by exposing them to a final rinse temperature of at least 180°F. Keep that number in mind as we explain to you…

What is a Booster Heater?

As most commercial building water heaters are set between 115° to 120°F, the hot water needs a boost to reach temperatures that kill bacteria and sanitize. This is accomplished by a booster heater. These are sometimes found built-in on larger, high-end dishwashers. It is more often found as a stand alone, external component.

There are two things to keep in mind when buying a booster heater for your high temperature dishwasher:

First, you need to know what temperature your building’s hot water consistently achieves. This is very important because you will need to know how many degrees the water needs to be increased to reach 180°F.

For example, let’s assume your building’s hot water can reach 115°F. You need a booster heater that can increase the water’s temperature by 65-70 degrees.

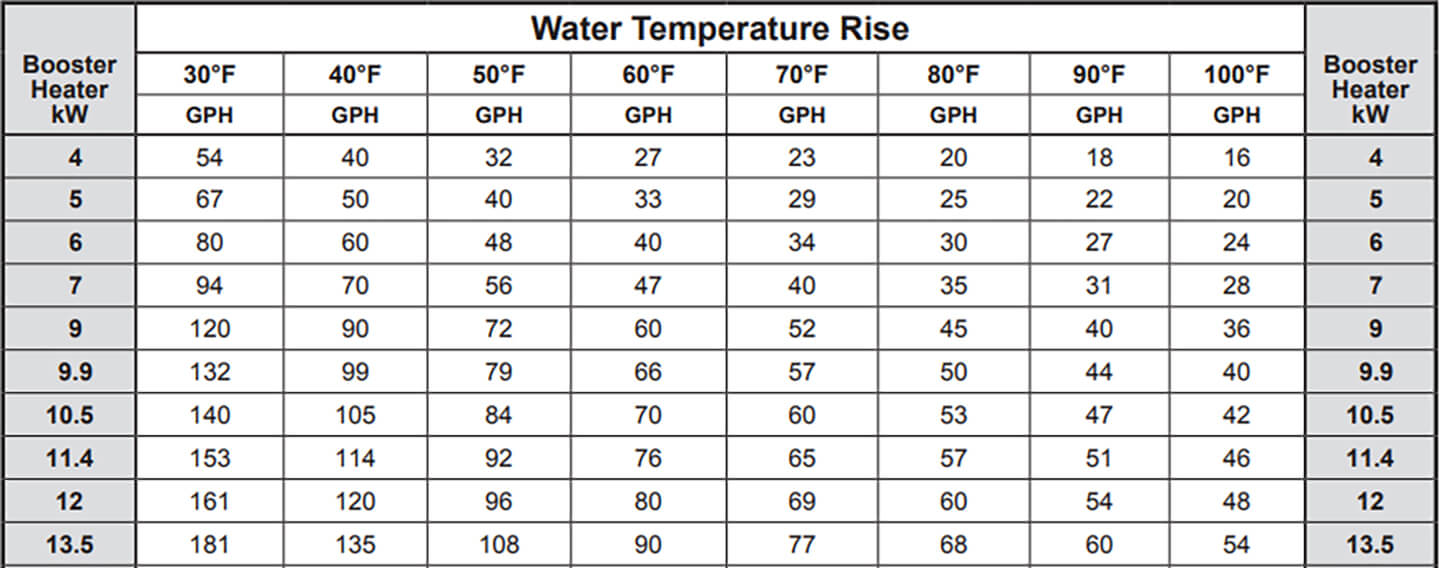

Second, you need to make sure the booster heater can output the gallons per hour (GPH) requirements of your machine. The higher the temperature needs boosted, the less GPH your booster heater will output.

Let’s use our previous example: You need to increase your building’s hot water by 70°F. You’re using a rack conveyor commercial dishwasher that uses 186 gallons of water per hour. Therefore, you will likely need a 36 kilowatt (kW) booster heater. Always check the specifications as each brand may vary.

Pro Tip: Always make sure you have an adequate power supply before you purchase anything!

Best 10 final rinse temperature for dishwasher - violetadvisors.com