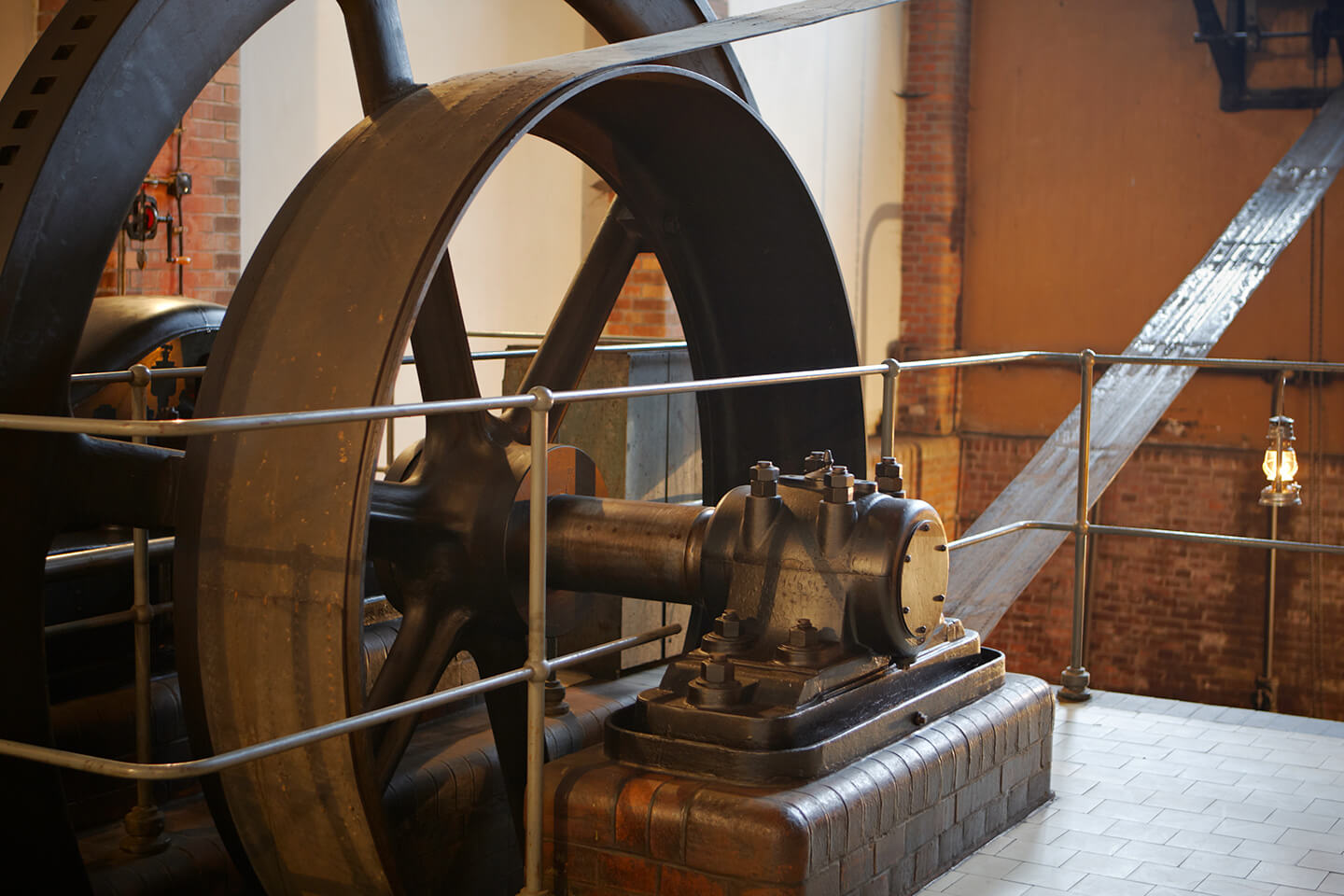

Within its origins, flywheeling represents the pursuit of the engineering holy grail of perpetual energy. The term flywheeling refers to the use of a literal, mechanical device called a flywheel. These typically heavy and spoked wheels are designed to conserve mechanical energy through inertia and the law of conservation.

Machines that produce large amounts of kinetic energy such as trains, power plants and performance cars continue to use flywheels to store and release kinetic energy.

If you’re a science buff and would like to learn more, ExplainThatStuff.com does a great job diving deeper into the science.

What is flywheeling?

You are probably asking yourself, “How does flywheeling apply to commercial cold storage?”

Refrigeration specialists in the foodservice industry conceptually borrowed the term “flywheeling.” Just as traditional flywheeling involves the conservation of mechanical energy; foodservice flywheeling involves the conservation of thermal energy.

As it applies to commercial refrigeration, flywheeling is when operators leverage the frozen contents of their freezer to maintain cold temperatures without electricity.

How does flywheeling work?

Food must be kept at or below specific temperatures to remain safe in cold storage. One of the more significant costs in the commercial refrigeration industry are the electricity costs.

To help balance the power load on a given electrical grid, power companies raise electricity rates during peak-usage times and lower rates during off-peak usage times.

Cold storage operators who participate in flywheeling cool their products well below the required temperatures during off-peak hours.

By doing this, operators pay the lower rates for their electricity, and in theory, store the “extra cold” in their products. During peak-hours when electricity is most expensive, they rely on their frozen products to act as thermal batteries.

The frozen products release their “extra cold” to keep the storage unit at safe temperatures. This continues until either the electric grid reaches off-peak hours, or the freezer approaches unsafe temperatures and needs cooled down again. Hopefully by this time, the foodservice operator will use less peak-usage electricity.

How risky is flywheeling?

The greatest risk with flywheeling is concern over damaging your frozen products. Operators are gambling to save energy costs while using frozen food as the gambling chips.

You should carefully consider the following risks before you attempt to flywheel to save energy costs:

- Constantly changing a food’s temperature can affect flavor and taste.

- Every time your freezer reaches the upper limit, you risk slightly thawing your food. This can cause moisture loss on a surface level, otherwise known as freezer burn.

- Flywheeling isn’t guaranteed to save you money. You purchase electricity at a lower cost, but you purchase more of it.

- Carefully monitor your energy costs. It may be just as likely that your energy costs break even by running your freezer to maintain consistent temperatures.

Should you try flywheeling for your restaurant?

Although we cannot recommend or encourage you try flywheeling with your foodservice cold storage, we can tell you that many operators do rely on it to save energy costs – but not all flywheeling is the same.

There are companies that specialize in more advanced versions of flywheeling, also known as Thermal Energy Storage (TES). TES uses materials that release and absorb heat very efficiently, which reduces the reliance on your food to act as the “thermal batteries.” Keeping these TES materials closer to the ceiling helps reduce the thermal exchange between food and the ambient air during the flywheeling cycle.

If you decide to give basic flywheeling a try, these are two bare-minimum tips to get started:

- Experiment in short intervals to get an idea of how it affects your particular food.

- Never let your food reach temperatures at or above safe levels for freezer storage.

Hello, Found your post interesting to read. Good Luck for the upcoming update.This article is really very interesting

Deep Fridge in Sindhudurg